One of the biggest components of a stagehand’s job on tour is load in. We often joke that we’re not paid to run the show, we’re paid to load it in and out and fix problems. (As an A1, your job is also about mixing the show, but the sentiment still holds true.) For me, I start prep work for load in even before we get to the venue: I chat with the house head and make up an advance for each city we go to. There will almost always be something that changes, but it’s easier to tweak a few things onsite than have to figure everything out from scratch.

(As a note, this is for larger tours that move once a week or less. It isn’t really sustainable to advance a tour that moves multiple times a week. Those smaller tours are the ones where your system is smaller so it’s more feasible to walk in and figure things out at the venue. That’s where you learn a lot of your problem-solving skills, which you’ll continue to use when you are on larger tours with more moving pieces that have to fit together. Tours rarely get easier; they just get bigger.)

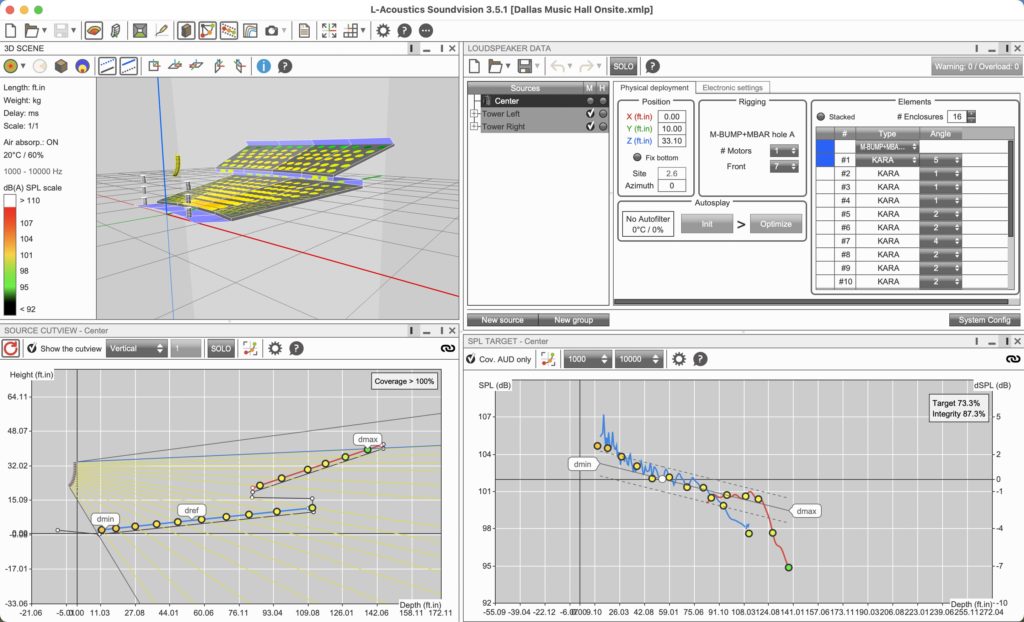

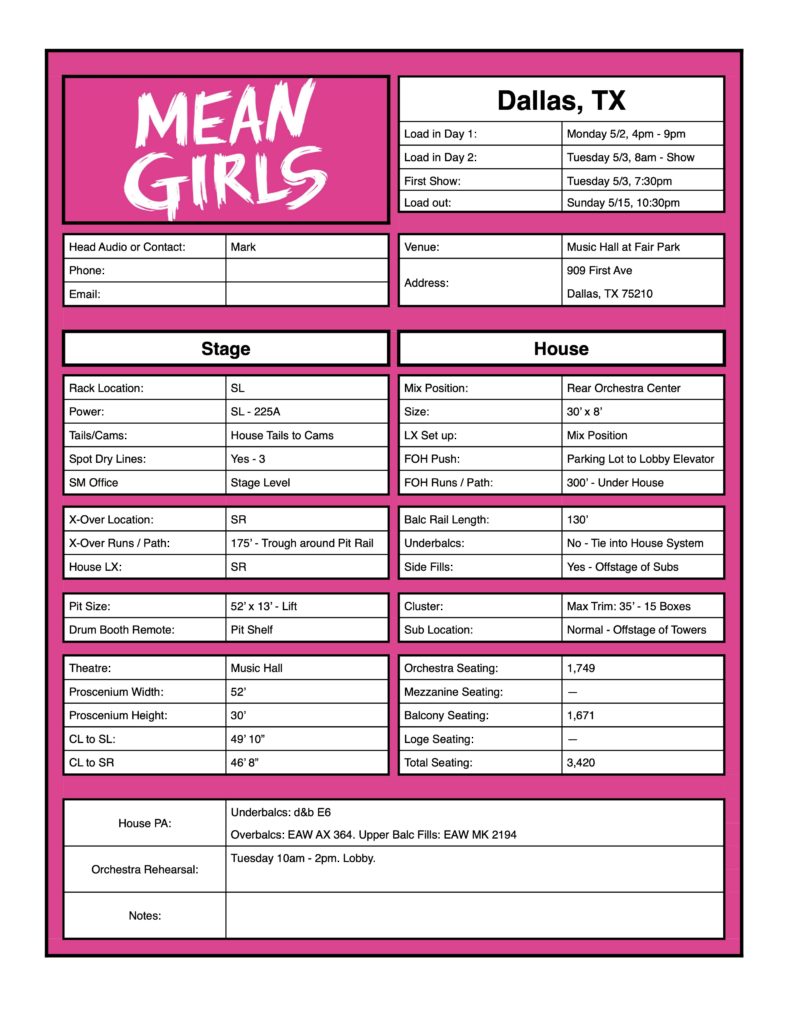

One part of my advance is an excel document that’s an overview of the venue and how we fit into it: what the dimensions of the stage are, where the amp racks will go (this is called Ampland), and how high the theatre ceiling is over the pit so I know how far I can trim the cluster out (which also tells me how many boxes I can use), etc. The other part is a summary from speaker prediction software: on Les Mis and Saigon, I used Meyer’s MAPP and on Mean Girls, I use L’Acoustic’s Soundvision. This tells me what angle I should use for point source boxes or what I’ll need to set the splays to for the arrays.

Once we get to the venue, the first step is to take a look around and talk to the audio house head. I’ve been on the road for a decade at this point and have been to all but maybe 8 of the 68 cities that we hit on Mean Girls. So for most of the venues, I have archival photos and paperwork and know roughly what I’m walking into, but things always change. New management, new crew, post-Covid renovations, at this point I can’t assume that it’s the exact same space I came to two or three years ago.

Once we get to the venue, the first step is to take a look around and talk to the audio house head. I’ve been on the road for a decade at this point and have been to all but maybe 8 of the 68 cities that we hit on Mean Girls. So for most of the venues, I have archival photos and paperwork and know roughly what I’m walking into, but things always change. New management, new crew, post-Covid renovations, at this point I can’t assume that it’s the exact same space I came to two or three years ago.

So you get the lay of the land and try to identify any problems with the plan. If the venue left the house cluster up, now is the time to take it down or fly it further out so I can hang mine. Are the holes to run cable under the stage too small for all the cable we have? Let’s talk to the house head about running it around the pit rail.

I’ll use a disto with an inclinometer (so it can give me both distance and angle) to double-check the accuracy of the room for Soundvision and the measurements for how high the cluster will actually be able to trim out. Going back to Soundvision, I put in the new info and see if I have to make adjustments or if I have to cut (or maybe can add!) boxes on the cluster.

A normal load-in on Mean Girls has a spotting call an hour before load-in starts. This is when the Carpenters measure out where motors will go on the floor and I have some time to take the measurements of the house. Load in itself starts with a 5-hour call on Monday evening. Then we break for the night and come back at 8 am Tuesday morning where we’ll work through the day (with a lunch and dinner break) until the end of the show around 10:30 pm.

So at the end of the spotting call, load-in begins and the trucks start unloading. Most of the trucks will be packed by department: Audio has a truck for most of our gear, Electrics (LX) has one for theirs, Carpentry has one for the deck, another (or maybe two) for set pieces, Props has another, Wardrobe and Hair one more. However, the first truck is usually mixed to give every department something to get started. (On smaller shows it’s more likely that most of the trucks are mixed.) Carpentry will get drops to hang and motors to rig so LX can hang truss, Audio can hang towers, and Carpentry can build scenic pieces. Audio and LX usually get cables we can run. On the first truck, we get our FOH (Front of House) runs that will connect Ampland that’s backstage to the console out in the house. These are usually the longest and most complicated cable runs, so it’s better to throw the entire local audio crew on the project and get it done and out of the way.

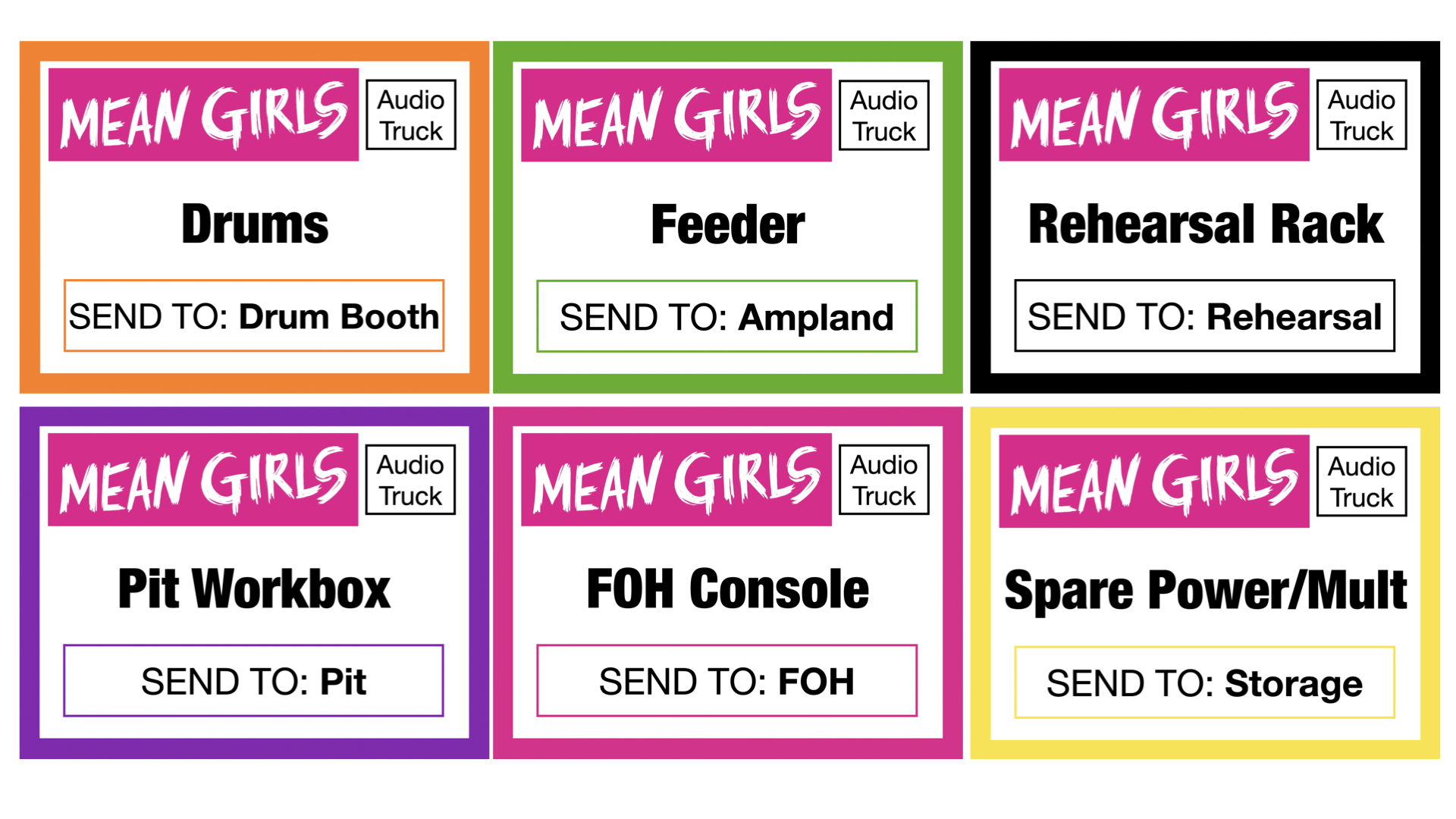

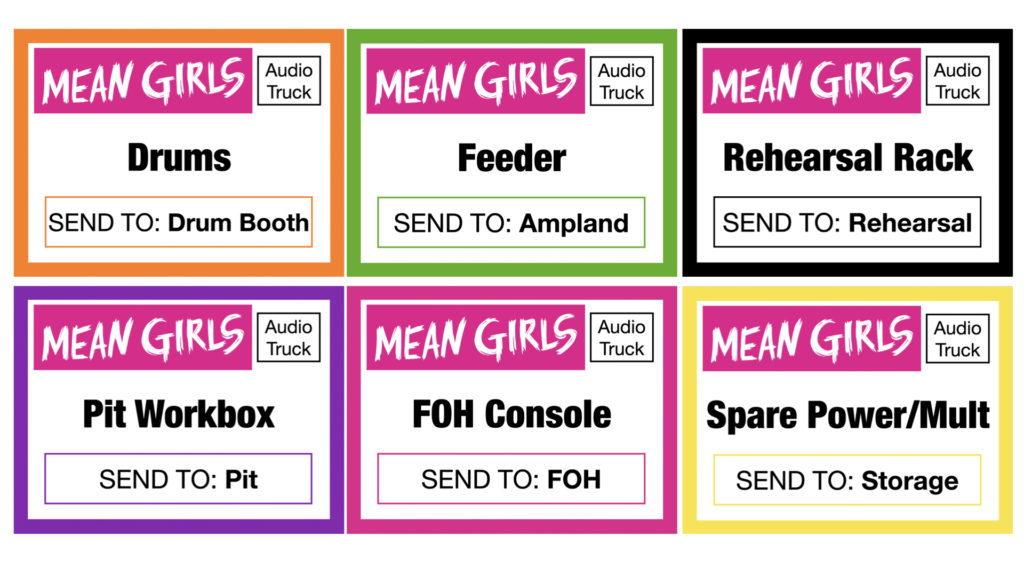

When our truck is ready to unload, we’ll dump all the cases, carts, and racks and find a place to put them in the theatre, usually denoted by a color code on the case label. Some, like spares (YELLOW), just go somewhere out of the way like down the side of a hallway or a rehearsal hall we’re using for storage. Others have consistent places: FOH (PINK) will always go to the theatre lobby, and Pit cases (PURPLE) will go down in an elevator to the basement level or off to the side to eventually ride down on the pit. Cases like Ampland (GREEN) change depending on the venue and where we end up putting our amp racks.

Once everything is off the truck, it’s time to work on projects. Most of the time the A1 will take care of getting the system set up: tip the console at FOH, build the towers and the cluster. The A2 will cover everything upstage of the proscenium: running all the cable (cross-stage, towers, cluster, pit, remote musicians, etc) and setting up com stations and onstage monitors. Some things, like the pit, can fall to either one. I’ve set it up as an A2, but on this tour, it worked better with the flow of load in that I, as the A1, set it up. This is where people and time management skills come into play. On most tours, I have 6 locals on the load in crew for audio, so my A2, Sherie, and I trade off crew so each of us has enough people to complete each job.

So, with all the cases off the truck, I’ll take the majority of the crew to FOH to tip the console: taking racks out of their cases to form a table and setting the console on top. It sounds easy until you remember that the SD7 (with part of the flight case) weighs around 400lbs. So I need at least 4 people to help me set that up safely. While I have the crew, Sherie has some time backstage to get the racks set where she wants them and start patching the FOH bundles we ran when they came off Truck 1. Then we split the crew and I take three people to build the towers (stacking three sections one on top of the other and bolting them together) and cluster (taking two carts, re-splaying the speakers, and connecting them all together to fly out), while Sherie gets the other three to start working on smaller projects like tying in feeder into power the racks or starting on com runs.

Load-in for Les Miserables tour (2017-2020) in Nashville, TN. (You can see the towers being built at the 0:22-0:27 mark)

After I’m done with the towers and cluster (and get rid of the large carts that the towers and cluster travel into clear space for others to work), I can send my crew to Sherie so she has everyone and can start on the longer cables runs that go across the stage, or into the pit, or to the Dimmer Racks (for cameras and stage monitors we have built into their truss).

While they’re working on those, I’ll make sure that we are clear of the pit (it’s usually an elevator that can come up to stage level to give us more space to build large pieces like truss or the towers) so Props can take the pit down and get ready to set up chairs and stands for the musicians.

Next, I can start on smaller, solo projects while Sherie continues with the crew. I prefer to be the one who patches things into racks. I’ve had enough well-meaning local crews that have accidentally plugged in something upside down, into the wrong place, or managed to slam an NL4 into a Powercon socket, that it’s easier and faster if I do it myself. So I finish setting up my console, patch everything in (with the help of more color coding), and power up.

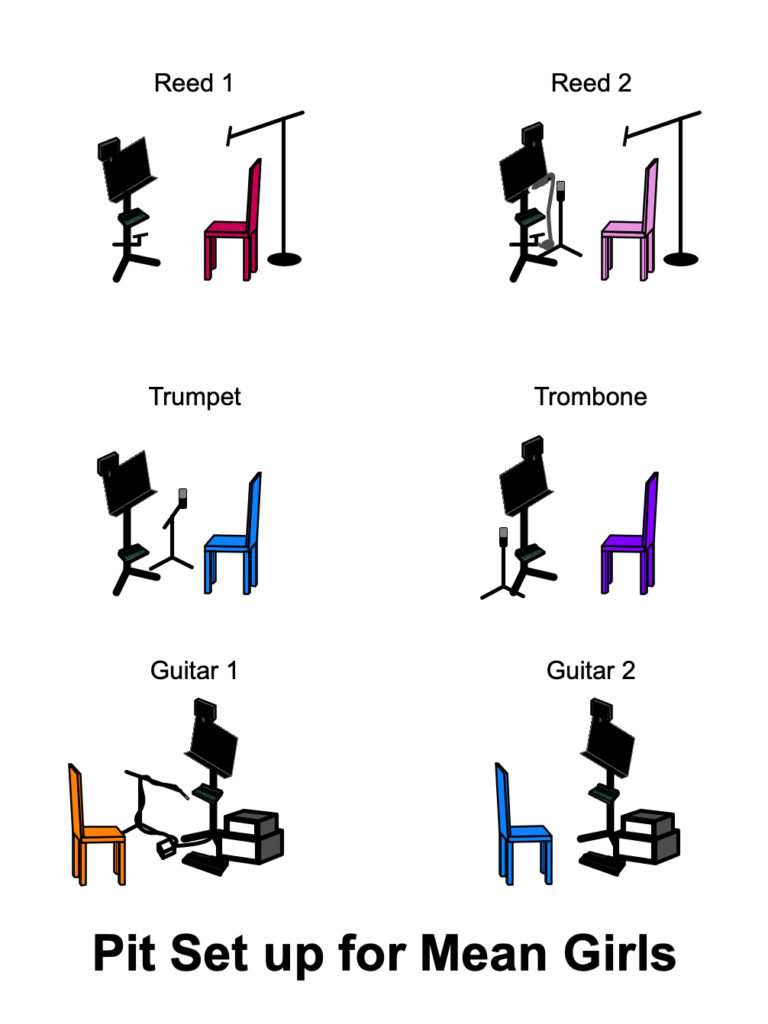

Then, I’ll head to the band rehearsal and work on that. This is something we only use during load-in so our show band (3 keyboards, drums, and a guitar) has a few hours to rehearse with the local musicians (2 reed players, trumpet, trombone, bass, another guitar, and a percussionist). This system consists of two speakers on stands (I get help for those, they’re heavy), and cables to run from a rackmount console to the various stations for all the electronic instruments.

This marks the end of Monday. My usual goal is to have the towers and cluster up so the pit can go down (or be ready at the top of the day on Tuesday) and most, if not all of the cross-stage runs are done. If we hit that point, we’re on track for the next day.

Tuesday morning we start our 4-hour call, power everything up, and continue working. I’ll take some time to make sure the towers sections are set at the correct angles (that disto comes in handy again) and I have sound coming out of all the right places, including any house system that we tie into to help supplement the touring system (under-balcony speakers or delays up in the balcony).

Once Props is done setting up chairs and stands in the pit, I’ll head down with a few locals to set up mics, conductor monitors, Avioms, and make sure everything is patched correctly for the musicians. While I’m in the pit, Sherie will work on deck with the rest of the crew to lag Front Fills in and continue setting up com stations as automation, the fly rail, and stage management gets set onstage.

Before we break for lunch, I’ll make sure that all my outputs are functioning and that SMAART and my wireless mic are set up for Quiet Time. (This is ideally when the Carpenters, Props, and LX are on their lunch break. I have an hour without people making noise on stage and they don’t have to listen to pink noise and loud music, so win-win.)

For Quiet Time, there are two general approaches: by ear with music and a disto, or using SMAART and an SPL meter. You use whichever your designer prefers, which on Mean Girls is the SMAART method. First I walk around with the SPL meter while a local is at the console to adjust levels and mute and unmute outputs as I tell them so I can set a consistent volume level across the house. Next, I’ll trade off with them, and give them the wireless mic to set at seats I’ve taped off so I can use SMAART to set the delay times for the matrix outputs. Finally, I’ll play music and walk the house to make sure that the delay and levels I set sound correct, making adjustments as needed.

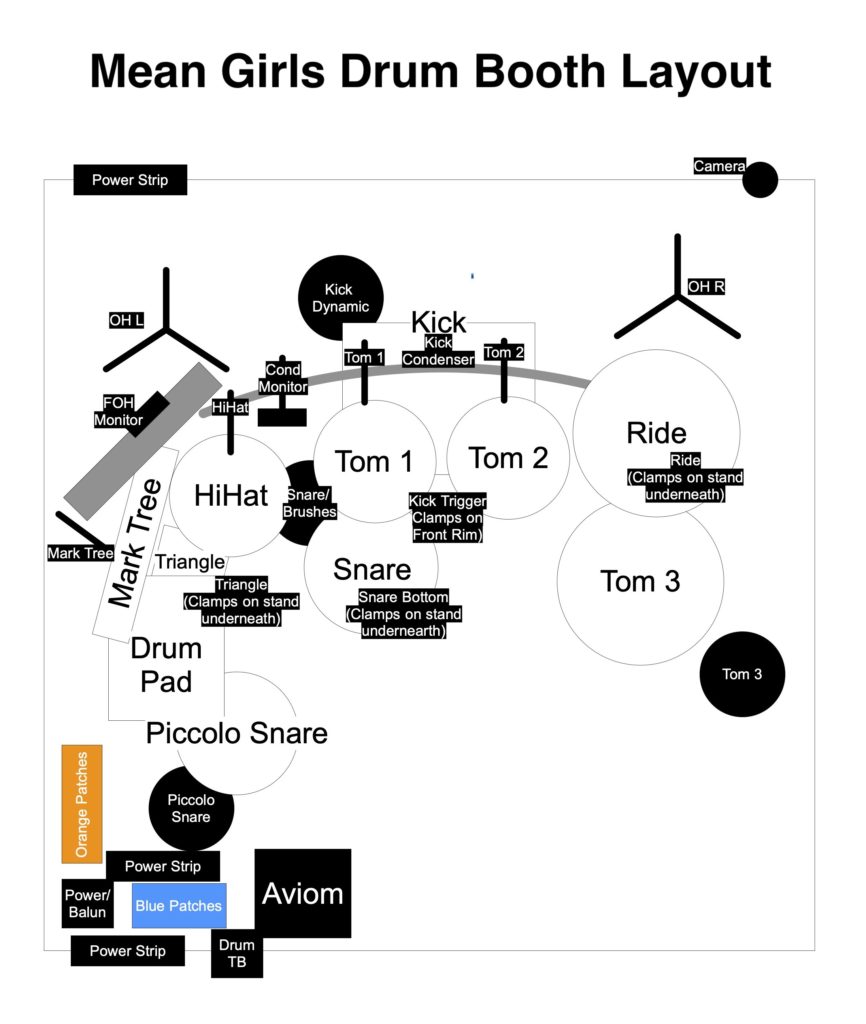

After Quiet Time we have about 2 hours to finish everything up before the dinner break. That involves sending the local crew to strike the band rehearsal I set up the day before, getting percussion set up in the pit and our drummer set up in his booth, and checking that everything is coming into the console at the right places.

At the same time, Sherie is working on tuning RF, focusing the onstage cameras that Stage Management and Automation use during the show, making sure all the onstage monitors are set up and having the local crew neaten up or tape down cable and sending cases to get backloaded on trucks or tucked away in storage.

When we’re show ready, we break for dinner, then come back for soundcheck. Sherie will battery up and get the mics ready for the actors while I’m in the pit adjusting mic positions for the musicians as they settle in. Then we’ll do half an hour with just the band, setting levels for the local players and adjusting the mix in the house. The last half hour adds the actors onstage and Sherie will come out front to mix the songs while I walk around the house to make sure there’s a good balance between the band and vocals and it sounds consistent in all the areas of the theatre.

Once sound check is done, I’ll make sure we’re set to start the show (MIDI checks, the console is in the right snapshot, etc) and Sherie will set out any practicals as part of her preset and walk our local audio through the cues they’ll have during the show.

At this point, we’re done with load in itself and ready for the show. Post-show usually means heading to a restaurant or bar for some late-night food and a drink or two to celebrate getting the show in. Then we look forward to tomorrow and the touring stagehand tradition of No-Alarm Wednesday!

Load-in for The Phantom of the Opera tour (2013-2020) in Ft Lauderdale, FL.